🔋 Faster and greener battery recycling

With ultrasound and weak acids, it is possible to recycle up to 99 percent of all metals in lithium batteries.

Share this story!

Lithium batteries are used in everything from mobile phones to electric cars. Being able to recycle the metals in spent batteries is necessary, both from an economic and environmental perspective.

Currently, recycling is a time-consuming process where hazardous substances such as sulfuric acid frequently are required for the extraction of metals found in the batteries. But researchers at KTH have developed a process that could make recycling significantly easier.

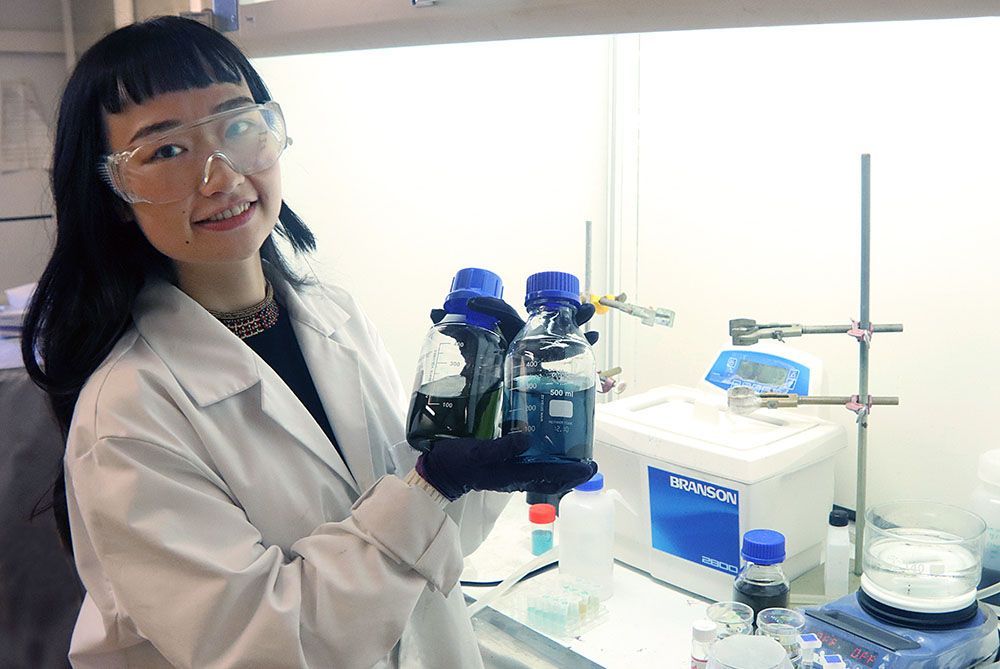

"We perform the metal extraction in half the time compared to what is normally needed and we get more metal ions than what is normally reported in the scientific literature. We also do it with mild acids such as acetic acid and citric acid instead of sulfuric acid, which is beneficial from all perspectives when it comes to both work environment and sustainable development", says Xiong Xiao, postdoc at the Department of Fiber and Polymer Technology at KTH and one of the researchers behind the new process, in a press release.

In total, it is possible to recycle as much as 99 percent of the metals in a battery using this method. In addition to lithium, nickel, cobalt and manganese can be extracted as well.

In addition to acids, ultrasound is used in the process and it is the combination of ultrasound and weak acids that is the breakthrough in research.

"Xiong Xiao's discovery is that with the help of ultrasound she has managed to remove the need for chemicals that are normally used, strong acids that are almost unmanageable. Through extensive studies, she has been able to see at what temperatures and concentrations of the kinder acids that the ultrasound best helps with the extraction", says Richard Olsson, research colleague and senior lecturer at the Department of Fiber and Polymer Technology at KTH.

The researchers will now go ahead and optimize the process even more before it can hopefully be used commercially.

"Now that we have reported this, researchers in the future can focus on optimizing the ultrasound even more. For example, with different intensities, frequencies and so on, for even faster extraction of the important and expensive metals that we want to recycle", says Richard Olsson.

By becoming a premium supporter, you help in the creation and sharing of fact-based optimistic news all over the world.