🔋 Minerals - the new sustainable oil

Minerals and metals are becoming increasingly important as the electrification of society accelerates. But mining is unevenly distributed across the world. In this article, energy consultant Ingemar Alvbom goes through everything you need to know about the ongoing global transition.

Share this story!

In December 2015, the world agreed to change course. With warming standing a severe threat to our existence, it must be stopped, and thus, the Paris Agreement was signed. China initially didn't want to participate but later joined, and the United States has now returned after some absence. The world's countries are now setting their roadmaps towards a fossil-free society. While the pace of change differs between the countries, the Paris Agreement remains the springboard. Carbon dioxide emissions must be eliminated, and "net zero emissions" are the goal.

The Paris Agreement means that coal, gas, and oil used for manufacturing, construction, heating, electricity, transport, etc., are to be replaced. The fossil must make way for the renewable.

Transports should be powered by electricity, houses heated by electricity while agriculture and industries should be electrified. The really heavy carbon dioxide emissions such as the coal, plastic, steel, and concrete industries should be made green and carbon independent.

Transformation requires humanity to once again dig underground, but this time to find metals that are bound in minerals. These will be the enabler of one of the greatest transformations mankind has ever gone through.

Minerals everywhere

In step with the increasing electrification, the need for minerals and metals also increases. The need mainly stems from batteries, but also other products. We use metals every day without necessarily thinking about it.

Rare earth metals are found in your tablet, they are spread over the fields, they are used in pharmaceutical production, in car tires, and in wind turbines.

Few may know that their cell phones vibrate with the help of a metal called tungsten. Gallium and indium are included in LED lamps. Cobalt is used in magnets and dental materials, platinum is found in electrolyzers that are important in hydrogen production.

There are minerals in paint and cosmetics, and we use metals to make jewelry and sculptures. Minerals and metals are also used to keep our environment clean by being part of components that filter the air we breathe and the water we drink. In total, there are about 80 metals, and most have names that are unknown to the general population, including lanthanum, cerium, praseodymium, neodymium, promethium.

In fact, the need for metals is so great that even recycling close to 100 percent would cover demand. But due to the high demand, recycling is becoming increasingly important.

If we look at the production of cars, the need becomes apparent. There are over a billion cars, and every year about 90 million newly produced cars are sold that contain ever-increasing quantities of these minerals, mainly in batteries. In a fossil car, 20 kilos of copper are used, while in an electric car, there are 70 kilos.

Most car manufacturers, including Volvo, Volkswagen, Ford Motor, Toyota, and BMW, have already said that they intend to become fully electric. Some say already by 2030 and others by the year 2050. Add to that that even buses and heavier vehicles will be electrified. The battery storage capacity must, therefore, gradually increase.

The batteries take over

Most people use more and more batteries in their daily lives. Therefore, we can conclude that the demand for metals - such as copper, cobalt, nickel, and lithium - which are key to the production of batteries will explode in the coming decades.

Research on batteries is in full swing all over the world. There's a clear and widespread desire to find new solutions to replace the metals that are rare or have problems with mining, such as cobalt, with other earth metals. This May, Tesla announced through the news that their Megapack will contain lithium iron instead of cobalt.

Most countries invest in the construction of battery factories, so-called "Giga Factories." China has an advantage because it started early. Of the world's 211 lithium-ion battery factories, only 12 are in the United States, while 156 are in China and 22 in Europe. In Sweden, Northvolt is building a battery factory in Skellefteå.

In the city of Badajoz in the region of Extremadura near the border with Portugal, Spain's first battery factory is now being established. It is special because it includes a plant for cathode production, two mines, and a lithium refinery.

Read more about lithium-ion batteries here.

In Sweden, there is the Swedish company SaltX which uses electricity from the sun and wind and heats up salt, which can then be stored for a long time. When you then add liquid, it becomes electricity again. At Mid Sweden University, a battery is made with paper and saltwater.

Not in my backyard

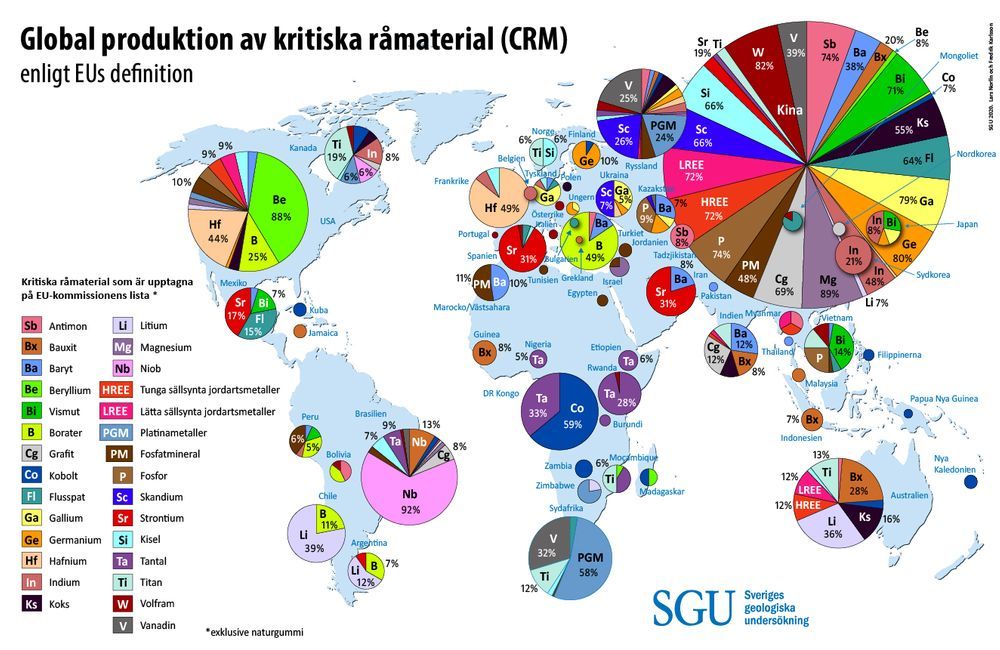

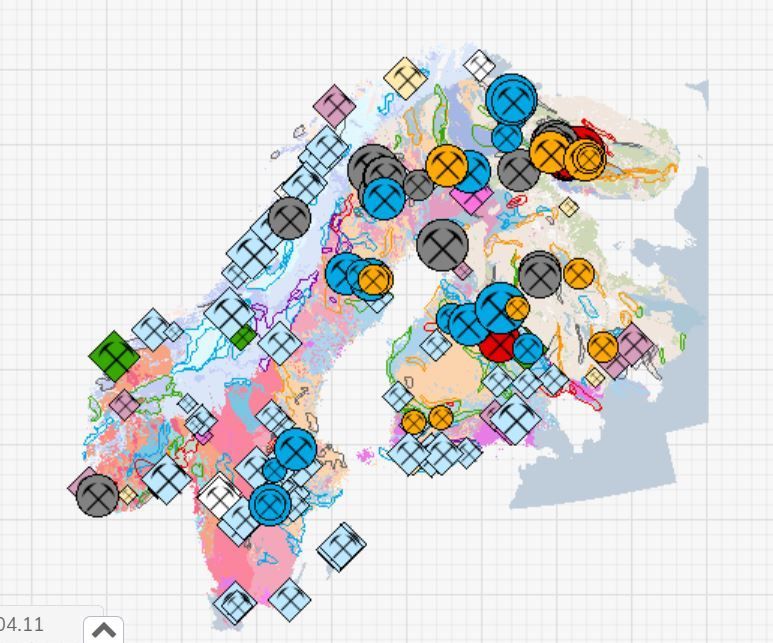

The map shows the deposits in the world and the Asian advantage. The picture below shows deposits in Scandinavia. From the map, it can be read that there is great potential in Sweden's immediate area.

But new mining establishments do not sound good to everyone. There's no shortage of people who adhere to the NIMBY mentality: Not In My Backyard.

Sweden is a country with 1000-year-old traditions of metal production, and we produce many different metals. 91 percent of all iron ore consumed in Europe comes from Sweden, with the five active iron ore mines that currently operate. At the same time, Sweden's production of iron ore is only one percent of the total mining in the world.

The EU qualifies certain minerals as critical materials and lists 30 pieces that are believed to be important to the European industries. Inventories have been made in all countries, and the positive thing is that there are a lot of assets, but it takes time for mining to get started.

The challenges of the mining industry

The mining industry has a dirty reputation, as pollution and poor working conditions pervade history. Few landowners become enthusiastic about when exploration is underway on their own land. But for decades, rules have been tightened, and in Sweden, there is environmental legislation that maintains a high standard compared with other European countries. Despite the fact that the mining industry has developed, the notions of the dirty industry remain with some.

There are still countries that have not tightened their management, lack environmental legislation, and where working conditions remain poor.

60 percent of all cobalt comes from Congo, where the exploitation of children in the mines has been reported, but more countries are starting cobalt mining and as mentioned earlier, solutions are on the way where cobalt can be replaced with other minerals.

In the Nordic countries, only Finland has started mining cobalt, and in the media we have seen headlines such as "Battery metals Finland's new gold". In Sweden, cobalt mines are in the planning stage in Norrbotten and Jämtland.

In 2020, the SOM Institute in Gothenburg conducted a survey of the attitudes of the inhabitants of Sweden towards the mining industry. Overall, they were positive about the industry, which is considered important for Sweden, and it was considered that it should be given the conditions to develop to ensure access to important metals, now and in the future.

Chinese dominance

For many years, China has seen it as important to control mineral deposits. Deng Xiaoping said as early as the 1990s that: The Middle East has its oil, but we have the metals. The insight into the value of minerals and metals has been with the Chinese for a long time.

China has large deposits of its own, but over the years has bought up deposits around the world. Some of the cobalt mines in the "Democratic" Republic of the Congo are owned by China and also many mines in Australia and Chile.

Globally, China is by far the largest producer with 86 percent of world production, followed by Australia at 6 percent and the United States at 2 percent. Virtually all imports of earth metals from China come to the EU.

If there is an interruption, conflict, pandemic, or natural disaster, countries can, of course, use their power to restrict access to these metals. Therefore, the security policy issue plays a significant role. Sweden has a good supply of several essential and sought-after metals and should be able to increase its mining of these, in order to reduce import dependence.

To give an example: during the war of the 1940s, the British aircraft industry had to recycle what aluminum they could to build the thousands of planes required due to imports being cut off.

EU countries must therefore make some of the mineral resources available and increase mining, and perhaps most importantly, the recycling of these metals must become more efficient.

Circular recycling

Only between three and eight percent of the metals are included in a circular system, according to the Swedish Geological Survey. Minerals are finite resources, so it is a must to get better at recycling. Metals are perfect recycled materials. They can be used, reshaped, and recycled over and over again.

There are good examples in Sweden - the smelter in Rönnskär is one of the world's largest recyclers of copper and precious metals from electronics.

The Northvolt battery factory, which will soon begin production, aims to be a little more environmentally friendly than most other battery factories. Their goal is for half of the material for the battery cells to come from recycled material.

The energy company Fortum already has a recycling unit for lithium-ion batteries. Did you know that the medals came from recycled minerals in the last Olympics?

The mining and metal industries can contribute to a circular economy. For that to happen, there's a necessity to change our view from; production-consumption to "Never ending" recycling. For it to succeed, the recycling aspect must be considered during the product design stage.

Transparency and traceability

There is a growing awareness that metals may come from processes with little regard for environmental considerations and poor working conditions. Many people who buy metals for their production want to be able to tell their customers that their product is OK, as there is a demand at the consumer level.

Therefore, there is a great movement in the industry towards finding a certification and traceability that works in the trade.

Svemin, a Swedish industry organization, runs TraceMet, a project where customers will be able to follow certified metals from mine to end-use. A recent news item was that Boliden had been granted membership in the International Council on Mining and Metals, ICMM. It is an international organization dedicated to a safe, fair, and sustainable mining and metals industry.

The EU has introduced new legislation to promote responsible mineral purchases by importers, called the EU Conflict Minerals Regulation. The legislation aims to ensure that importers of critical minerals have a responsible procurement of these and to increase traceability at the supplier level. The regulation is largely based on the OECD's guidelines on due diligence in the supply chain.

The World Economic Forum's mining and metal blockchain initiative consists of seven really large metal and mining companies that try to design and explore blockchain solutions. The aim is also to increase responsible purchasing in the industry and accelerate new solutions for visibility in the supply chain, and to make demands on the environment, social responsibility, and governance.

One member is multinational Rio Tinto, which believes that the blockchain solution will help customers become aware of the origin of their aluminum products. The company hopes that this will lead to end-users being able to make more informed choices about the products they buy.

In Norrland, Sweden, mining companies LKAB/SSAB are running a project that's received a lot of coverage, called Hybrit. Instead of burning coal, they want to process the ore using hydrogen-powered technology. The investment is at an advanced stage and has inspired all the world's steel giants to start similar hydrogen projects. Everyone wants to be involved in producing green steel, which is already in demand in the world.

Simultaneously, this introduces the need for a green stamp. Customers want to know that they're buying green steel and may at least initially accept a slightly higher price. Since the really big companies now also have a serious desire to produce green steel, there is much to suggest that the introduction of certification is accelerated and has a major impact.

Mining goes digital and becomes cleaner

In the mines, automation, digitization, and AI are the big words of praise. The management of the mines is fundamentally changing. Operators today sit far from the mining site and steer driverless vehicles. When a machine breaks down, other autonomous vehicles arrive to recover it. It is about creating a safer mining operation, a better air environment, and reducing the mines' environmental impact.

The development creates conditions for producing more, and that the amount of scrap ore is reduced. Digital progress is still in its infancy but has all the prerequisites to move forward quickly.

The mines in Sweden now go from wifi to 5G, and IoT is coming little by little. More and more AI projects are started. In the Insite-X project, the University of Skövde, together with Outokumpu and Ovako, is investigating whether AI can be useful in the iron and steel industry's production processes. AI projects must analyze large amounts of data and machine dynamics. With new X-ray machines, information is retrieved, and AI determines which ore is more or less minable.

Battery-powered driverless vehicles will become the norm. Autonomous drones, together with scanners, become an effective way to investigate inaccessible areas in the shaft. Robot technology in the mines is becoming more and more common. This leads to the need for fewer and fewer people at the mining front.

Battery technology means that diesel vehicles and exhaust fumes are eliminated. Sensors control the supply of fresh air in a cheaper and smarter way.

Summary

We are facing a major change where renewables take over. Mankind is ready with drills and machines to once again search deep underground for the raw material that will build the new world.

There's a broad-spread desire to ditch the dependence on dirty businesses, and now the possibility exists. Researchers are working feverishly to develop alternative materials for batteries and electronics. It is important not only for Sweden but for the whole world, for a future with prosperity and a good living environment. Our attitude towards the mining industry must change. Otherwise, there is a risk that access to critical minerals will become a bottleneck in the green transition.

The mineral industry creates many jobs, so let's develop it further. Society must see that the mine is an attractive workplace that uses all the technology that other industries use. The previously dirty mining work has changed shape into a real future job.

We in Sweden can be a driving force. We have the Luleå University of Technology, LTU, which many consider being a leader in Europe in mining research. Our mining industry is at the forefront. We now need a changed and faster permit management for a sustainable society to take shape.

By becoming a premium supporter, you help in the creation and sharing of fact-based optimistic news all over the world.