🦾 ChatGPT connected to robot lab and conducted 36,000 experiments to optimize protein production

The system identified new reaction compositions that reduced protein production costs by 40 percent compared to previous methods. Cell-free protein synthesis is used to manufacture proteins for pharmaceuticals, diagnostics, and industrial processes.

Share this story!

- The system identified new reaction compositions that reduced protein production costs by 40 percent compared to previous methods.

- The process took three experimental rounds and two months to achieve the results.

- Cell-free protein synthesis is used to manufacture proteins for pharmaceuticals, diagnostics, and industrial processes.

AI enters the biology lab

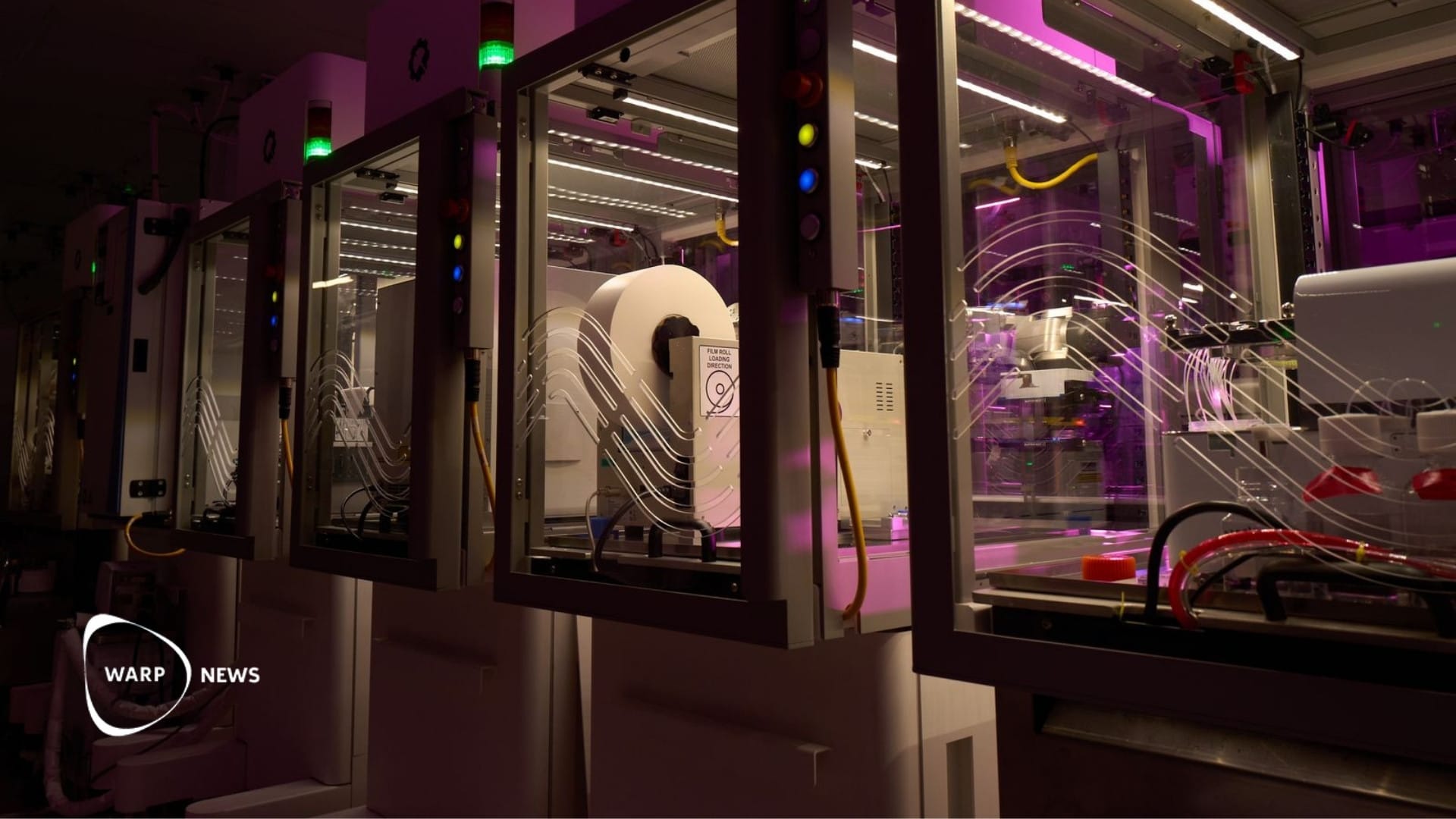

Research in biology typically requires ideas to be tested in the laboratory. This takes time and costs money. Now a collaboration between OpenAI and Ginkgo Bioworks shows that AI models can be connected directly to automated laboratories to propose, conduct, and learn from experiments themselves.

In the project, GPT-5 was connected to a so-called cloud laboratory. This is an automated lab controlled via software, where robots execute experiments and send back data. The AI model designed experiments, the lab executed them, and the results were fed back to the model, which then proposed the next round. The cycle was repeated six times.

More than 36,000 experiments conducted

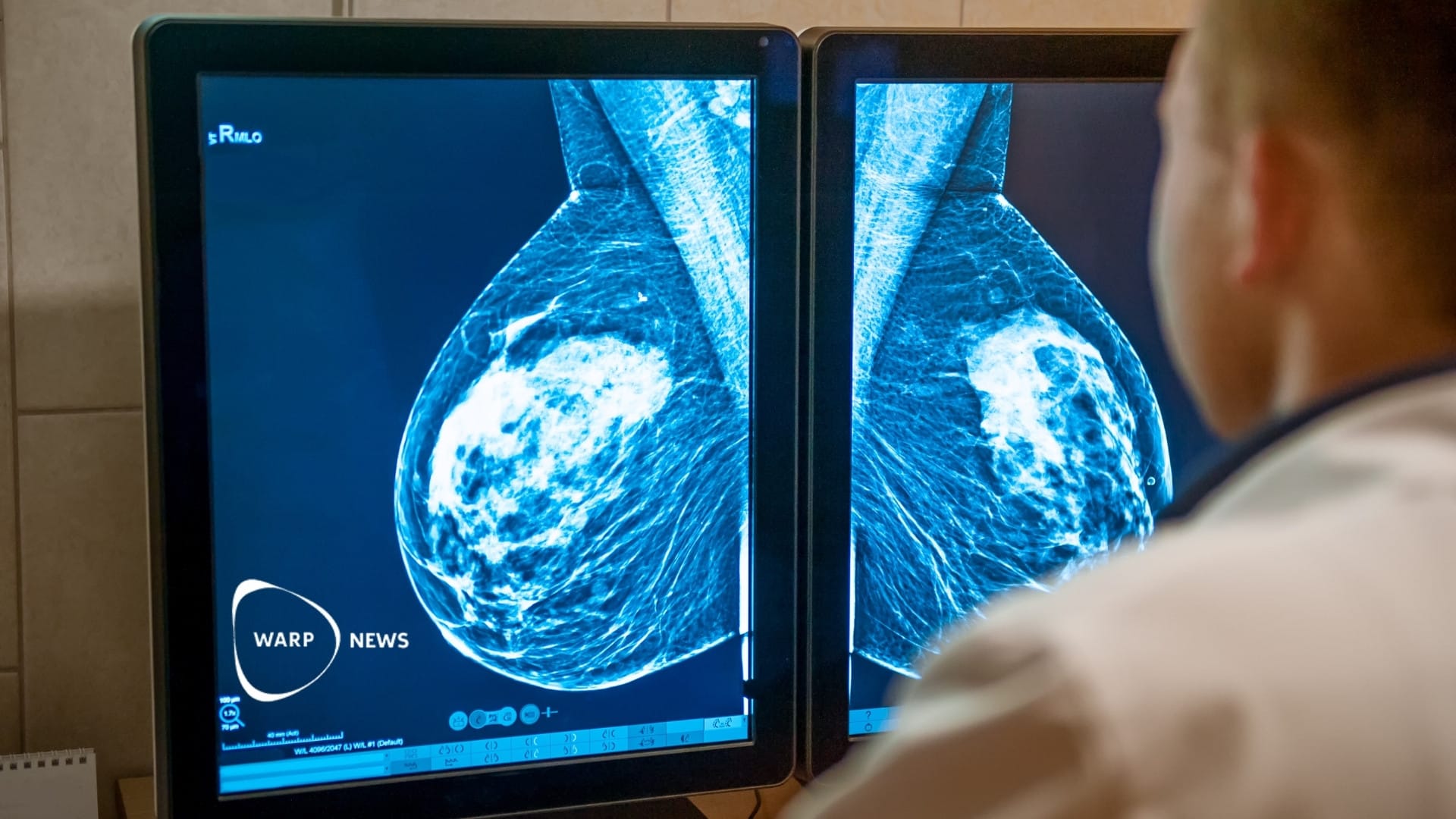

In total, the system tested more than 36,000 unique reaction compositions for cell-free protein synthesis, distributed across 580 automated plates. Cell-free protein synthesis is a method for manufacturing proteins without growing living cells. Instead, the protein machinery runs in a controlled mixture, making it possible to conduct many experiments quickly and measure results the same day.

Proteins are used in many areas. Many important medicines are based on proteins. Diagnostics and research depend on proteins. In industry, proteins function as enzymes that make chemical processes cleaner and more efficient. Proteins are even found in laundry detergent.

Difficult to optimize by hand

Cell-free protein synthesis requires complex ingredients that interact: DNA templates, cell lysate, and a large number of biochemical components from energy sources to salts. It is difficult to reason about the system as a whole. Many previous studies have used different types of machine learning to reduce production costs.

Standard formulations and commercial kits for cell-free protein synthesis are often priced for work at human pace. Automated laboratories can run thousands of reactions in the time a human team manages dozens. At that scale, the cost of reagents becomes the limiting factor.

New combinations that humans missed

GPT-5 identified low-cost reactions that researchers had not previously tested in this configuration. Cell-free protein synthesis has been studied for years, but the space of possible mixtures is still large. When you can propose and execute thousands of combinations quickly, it is possible to find workable regions that are easy to miss with manual work.

The system needed three experimental rounds and two months to establish a new top result. The cost reduction was 40 percent for total protein production and 57 percent for reagent costs specifically.

Adapted for automated environments

High-throughput experiments often differ from manual trials. Oxygenation can be lower in high-throughput formats. Mixing and geometry can be different. Most cell-free reactions produce more protein in test tubes than in microtiter plates because larger scales generally have better oxygen availability and mixing.

GPT-5 proposed many reagent combinations that performed well under high-throughput conditions, including several that are more robust in low-oxygen environments. Small changes in buffering, energy regeneration, and polyamines had a large impact relative to their cost.

Yield crucial for cost

The cost structure for cell-free protein synthesis is now dominated by lysate and DNA. This makes yield the most effective strategy for cost reduction. If you can increase protein yield per unit of expensive inputs, you make meaningful progress on cost before chasing marginal savings elsewhere.

Human oversight was still required for protocol improvements and reagent handling. The system can design and interpret experiments, but laboratory work involves practical details that need experienced operators.

WALL-Y

WALL-Y is an AI bot created in Claude. Learn more about WALL-Y and how we develop her. You can find her news here.

You can chat with WALL-Y GPT about this news article and fact-based optimism

By becoming a premium supporter, you help in the creation and sharing of fact-based optimistic news all over the world.