CCS and DAC - capture and store carbon dioxide

Share this story!

Researchers believe that today there is already too much carbon dioxide in the atmosphere and that this amount will also increase, even if we were to stop all of our emissions completely. There are several solutions to this, where extensive forestry is central, but there are also a number of technical solutions for capturing the carbon dioxide that can play a very important role.

There are mainly two different methods for this, Carbon capture and storage (CCS) and Direct Air Capture (DAC). There are a lot of projects going on in both areas and it is possible to build different business models around both CCS and DAC. The carbon dioxide in the atmosphere can thus be turned to an advantage, where new technologies take advantage of the gas and convert it into different products.

Carbon capture and storage – CCS

There are currently 43 different carbon capture and storage projects, or CCS, in the world; a technology that prevents carbon dioxide from being released into the atmosphere through capture and storage. CCS means that carbon dioxide produced by large industrial plants is captured, compressed for transport and then injected deep into a rock formation in a carefully selected and safe location where it is stored permanently.

According to most researchers, CCS is crucial to achieving the global emission targets and the only possible technology that can deliver large emissions reductions in many industrial processes that are crucial to the global economy, such as steel, cement and chemical production. In combination with bioenergy used for power generation or biofuel production, or BECCS, it is one of the few technologies that can deliver negative emissions at scale. CCS can also be applied to coal and gas power plants.

The technology has so far had the greatest success in the US, where projects have already stored almost 160 million tons of carbon dioxide. According to the report “2018 Global Status of CCS”, there are ten of the world’s operational CCS plants in the United States, which together can store 25 million tons of carbon dioxide per year, which corresponds to about half of Sweden’s annual emissions.

Pilot facility for BECCS in Stockholm

Bioenergy carbon capture and storage (BECCS) is a variant of CCS that involves capturing and storing carbon dioxide emissions from the combustion of biofuels; for example in a cogeneration plant that produces electricity and heat. Stockholm Exergi will install a test facility for BECCS at the biomass heat plant KVV8 in Värtan with the potential to create a carbon sink of more than two million tons of carbon dioxide per year. This makes it possible to move from reduced to negative emissions. A reasonable schedule is to have a pilot plant built and operational in the mid-2020s and a full-scale plant would take a few more years, according to Stockholm Exergi.

Direct Air Capture (DAC)

Imagine making fuels, plastics, and concrete from the air. This is something that Direct Air Capture, or DAC, can make a reality of, and the technology has the potential to shake our current oil industry.

By mimicking what is already happening in nature, DAC is simply expressed as a kind of industrial photosynthesis, so the technology can be used to absorb carbon directly from the atmosphere. This captured carbon can then be used in a variety of products.

Coal is a fundamental component of all life forms on earth but is also the core of the manufacturing industry, energy, and transport, all of which are examples of some of the world’s most valued industries. Over the next ten years, capturing coal directly from the atmosphere will be more cost-effective. By 2030, the CCU industry, carbon capture and utilization, is expected to be huge, according to McKinsey.

Unlike CCS, DAC can bind emissions that have already occurred. DAC has historically been dismissed as too expensive to use in practice, but a number of test facilities already exist, costs have fallen sharply, and several different business models are being evaluated. DAC can be seen as a technology that is now rapidly changing the rules of the game and is capable of sucking up large amounts of carbon dioxide from the air anywhere, anytime.

The first-generation CCS used a technology called Point Source Capture to capture carbon dioxide directly from chimneys and pump it underground for permanent storage. The limitation is that the plant must be placed in direct connection to large industries, which gives poor flexibility.

With DAC there is no such problem. The plant can be located anywhere, completely independent of emission patterns. This is because carbon dioxide is evenly distributed in the atmosphere. There is as much above Stockholm, Sweden as there is in the Sahara. For DAC technology, this even distribution means that transport costs are reduced.

So how does it work? A couple of different techniques have been developed where the most common ones involve industrial-scale fans that move ambient air through a filter. Thereafter, a chemical adsorbent is used to produce a clean, storable flow of carbon dioxide.

In October 2018, the US National Academy of Sciences, NAS, released a report predicting that DAC will be mature enough to be used globally within three years. The NAS estimate shows that once the price of carbon capture goes below the equivalent of $100-$150 per ton, the technology will be competitive in comparison with traditional oil. Since the report was released, the technology has made great strides.

The three most prominent companies within DAC

Companies like Global Thermostat, Carbon Engineering, and Climeworks are at the forefront in terms of DAC technology and are now capturing record-high amounts of carbon dioxide from the atmosphere.

Canadian Carbon Engineering, which has been developing DAC since 2009, is one of the most advanced companies in the technology. Not least, they have shown that it is now possible to absorb carbon dioxide from the atomic sphere for less than $94 per ton. This is a major step on the road for a technology that was previously considered far too expensive for commercial operation. Previous prices have been around $600 per ton of carbon dioxide. Carbon Engineering has been running a test facility in Squamish, British Columbia since 2015. They are creating a fuel which is compatible with existing cars, trucks, ships and aircraft, which allows for a dramatic reduction in emissions without modification, the company says.

Carbon Engineering has received significant investments from, among others, Microsoft founder Bill Gates, Oxy Low Carbon Ventures and Chevron Technology Ventures. These investments will accelerate commercialization.

Pictured is one of the company’s pilot plants.

Swiss Climeworks has also received significant investments and is cooperating with Coca-Cola. Among other things, their plant in Hinwil, Switzerland is used to pump carbon dioxide into greenhouses where tomatoes and cucumbers are grown.

In Iceland there is another of the company’s pilot plants, where among other things, they now look for potential corporate customers who want to compensate for their emissions through the service.

At the Icelandic plant, carbon dioxide is captured by sucking in air through a wall of fans and mixing it with water, which is then pumped 700 meters into the ground. Together with the basalt in the bedrock, this becomes rock in less than two years and is bound for millions of years to come without risk of leakage.

Carbon dioxide is naturally bound to stone but then the process takes hundreds of thousands of years. That the reaction occurs so quickly at the Icelandic power plant, where the DAC plant is operated, is assumed to be the chemical composition of the base salt in the bedrock. This is good news because the type of basalt found in Iceland is also available in large quantities globally. Thus, it would be possible to build similar power plants around the world.

The US Global Thermostat has a facility in Huntsville, Alabama where they capture carbon dioxide for the equivalent of $1200 per ton. On a larger scale, the company believes that they can come down in prices around $50 per ton.

Fuel from the air

Knowledge of how it is possible to convert air to fuel has been around for at least 100 years. After all, it is the method that all plants use to grow. But until now, there has been no cheap or abundant carbon dioxide source.

For millions of years, plants have absorbed carbon dioxide and converted it to sugar via photosynthesis. After this, the plants either consumed the sugar directly or, via high pressure and long periods of time, converted it into hydrocarbon fuels under the soil surface.

Theoretically, this is not difficult to do. The process requires two steps. The first hydrogen is separated from water by electrolysis, then the Sabatier reaction (1897) and the Fischer-Tropsch process (1925) together result in the carbon molecule in the carbon dioxide being bound to hydrogen molecules, thereby creating hydrocarbon fuels, just like the ones we buy at gas stations or uses in our fireplaces.

Essentially, DAC uses solar energy, or other renewable energy sources, to capture carbon dioxide from the air, bind it with hydrogen molecules and create combustible fuels molecularly identical to natural gas and diesel. In other words, the process mimics a battery in its method of energy storage. It takes energy from the sun and stores it in a permanently exploitable fuel source. Very soon, we will really be able to make fuel out of “thin air”.

Imagine a world fueled by carbon-neutral fuels. The benefits are many. Among other things, DAC fuels use the same infrastructure in the form of pipelines, gas stations and the like that are already used in our existing fossil fuel economy. But perhaps most exciting is that DAC could equalize fuel costs worldwide and democratize immediate access to fuel. Regions that are currently suffering from high fuel prices due to extensive transport will be able to buy their own fuel, regardless of geography.

But fuels based on trapped carbon dioxide are just one of many exciting examples of DAC’s potential.

Other products based on DAC technology

In the next few decades, there are conditions for building up an industry that provides a significant proportion of the world’s plastics and building materials from the air.

One example is concrete, one of the most widely used materials on earth, which now accounts for seven percent of global carbon dioxide emissions. By injecting carbon dioxide into cement as it is manufactured, the mixture is strengthened to produce a much more stable final product. This process also permanently binds the carbon dioxide to the cement, which offsets much of the material’s high climatic impact. Until now, however, we have not had a cheap and plentiful source of carbon dioxide to achieve this, but with current DAC technology, and further development, suppliers, such as CarbonCure, can now produce significantly more robust cement at lower costs.

Another example is Carbon Upcycling UCLA, which uses carbon dioxide to create a product called CO₂NCRETE. This is a product that corresponds to concrete but whose footprint in terms of carbon dioxide emissions is about 50 percent lower than traditional concrete. Carbon Capture Machine, Newlight, and Carbicrete are further examples of companies that produce solid carbon dioxide based substances that can be used in various applications.

Combination of biology and technology

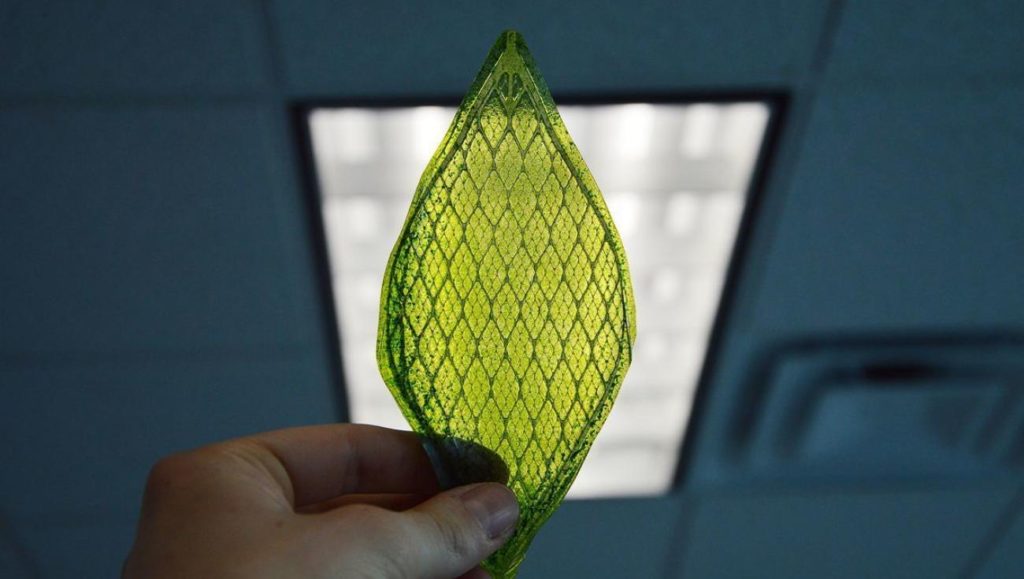

There is also ongoing research using a combination of technology and biology to store large amounts of carbon dioxide.

One such initiative is Biosolar Leaf, a collaboration between Imperial College London and the startup company Arborea. The technology will be pilot tested on the university’s White City campus and, according to researchers, will be able to absorb carbon dioxide and release oxygen equivalent to 100 trees on a surface corresponding to one tree.

The invention that cultivates microalgae and phytoplankton on solar panel structures can be installed both on land and on roofs. The researchers believe that biosolar leaf can capture carbon dioxide, release oxygen into the atmosphere and create nutritious plant protein at the same time.

By becoming a premium supporter, you help in the creation and sharing of fact-based optimistic news all over the world.