💧 Recyclable material turns salt water into drinking water in 30 minutes

If we can find a scalable way to desalinate seawater, water scarcity would be a thing of the past in many parts of the world. MOF material can be the way there.

Share this story!

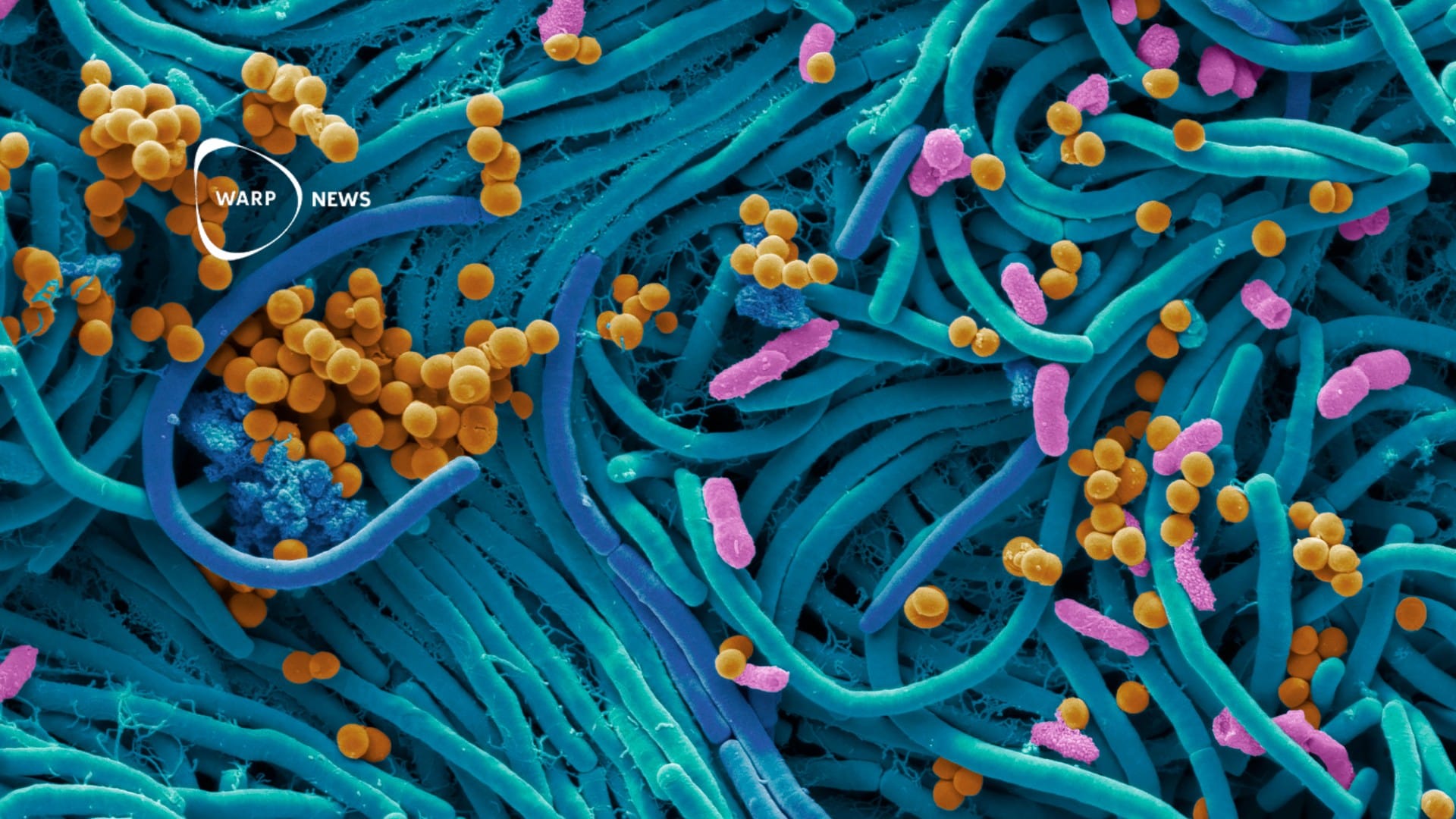

Access to clean drinking water is a growing challenge for many communities. If we can find a scalable way to desalinate seawater, water scarcity would be a thing of the past in many parts of the world. This is not an easy task, but great progress has been made in the field in recent years.

MOF, or metal-organic framework, is a material that is very promising, according to a study published in Science Advances . The material can filter pollutants from seawater and generate large amounts of fresh water with less energy than other desalination methods.

MOF materials are extremely porous and can be spread to cover large areas. In fact, it is the material that has the largest inner surface of any known material. Unfolding, a single gram of the material can theoretically cover a football field. It is this complex internal structure that makes MOF perfect for capturing, storing and releasing molecules. New research on the material shows that it can function as carbon dioxide emission sponges and chemical sensors. Because they work so well to capture small molecules and particles, they are also excellent for purifying water.

Ready in 30 minutes

The team behind the study used a MOF called PSP-MIL-53 and captured salt and contaminants in brackish water and seawater. Within 30 minutes, the material was able to reduce the total amount of solutes dissolved in the brine from 2233 parts per million (ppm) to below 500 ppm. This is well below the 600 ppm that the World Health Organization WHO recommends for safe drinking water.

MOF could produce as much as 139.5 liters of fresh water per kilogram of material every day and can be quickly and easily cleaned for reuse by placing it in sunlight.

Other desalination techniques such as thermal desalination and reverse osmosis have disadvantages such as high energy consumption or heavy chemical use.

Currently, reverse osmosis membranes are the most common technique for water filtration and they operate on a fairly simple principle. The pores of the membrane are large enough for water molecules to pass but too small for most pollutants. The problem is that these systems require water to be pumped through relatively high pressure to function. So a lot of energy is required.

Both clean drinking water and lithium

The researchers believe that their MOF method is the most effective method to date in terms of time, cost and energy consumption. The possibility of creating drinking water from salt water with only a reusable material and sunlight can be revolutionary to meet the future need for drinking water.

But clean drinking water is actually not the only end product of the MOF membrane. Lithium is in high demand due to the lithium-ion batteries that power everything from smartphones to electric cars. These ions are left in the spongy structure, ready to be used.

So it is not only drinking water that the MOF material can solve. Maybe it can also provide us with materials for the batteries of the future.

By becoming a premium supporter, you help in the creation and sharing of fact-based optimistic news all over the world.