☀️ Photovoltaic panels are now facing their latest challenge: recycling

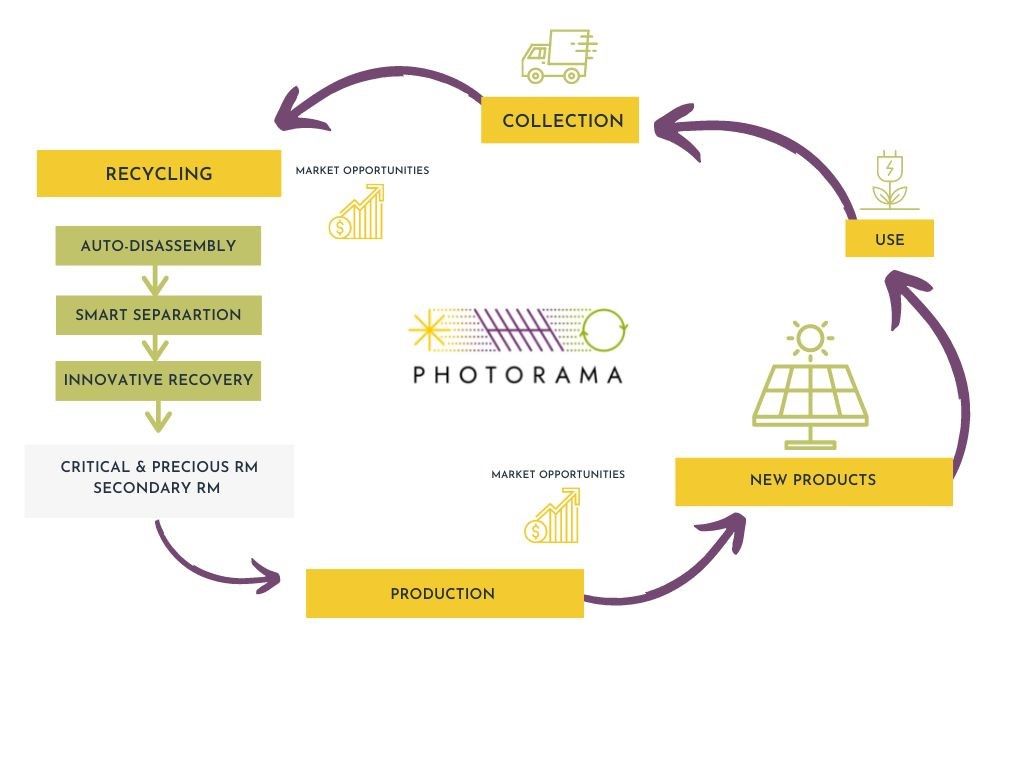

The EU-funded PHOTOTRAMA project aims to develop innovative technology for recovering almost all raw materials coming from waste panels, not dispersing polluting metals into the environment and making the most of all the valuable parts.

Share this story!

There is a huge generator in the sky continuously producing clean energy, and it should continue to run for several million years: The sun.

We have the technology to extract this emission-free energy with long-lasting panels. So, the first and most fundamental step to achieving a zero-emissions world is to implement the largest number of photovoltaic panels everywhere: on the roofs, over the industries, and in new electrical plants called solar fields.

Time and cost aside, the technology seems well established. Is there any detail still holding back their development?

The end-of-life issue

In the report "End of Life: Solar Photovoltaic Panels" by the International Renewable Energy Agency (IRENA) it's predicted that by 2050 solar energy will produce eighteen times the current global capacity. For that year, the panels to be disposed of will amount to approximately 78 million tons.

The end-of-life of the panels still remains their weak point. The panels contain both useful conventional resources such as aluminum, copper, glass, and valuable materials (silicon, silver, gallium), as well as hazardous materials (lead, cadmium, selenium).

These are organized in a series of layers firmly heat-sealed to withstand the weathering for about 25-30 years.

Separating the various layers from their polymeric glue, disassembling the cells, recovering the critical parts, and treating the dangerous materials: the recovery task is not at all simple.

Indeed, there is evidently a lack of efficient recycling technologies.

Current recovery treatments can include quite inefficient techniques such as shredding photovoltaic modules causing the loss of all valuable parts, or treatment at high temperatures with the disadvantage of emitting greenhouse gases.

The most effective processes act through chemical or physical treatments that overall require a consistent manual human contribution, limiting the economic advantages and production speeds.

In all cases, a certain percentage of precious materials is lost, with the risk of dispersing hazardous materials into the environment.

What is needed is a way to untie the materials from the glue layer without highly emissive heating, using an easily automatable technology, which can work for all the various types of panels, recovering almost 100% of the materials and not dispersing heavy metals in the environment.

The PHOTOTRAMA Project

The EU responds to these challenges by funding approximately € 8.4 million for the PHOTOTRAMA project, an acronym for PHOtovoltaic waste management - advanced Technologies for recOvery & recycling of secondary RAw MAterials from end-of-life modules. The project carried out by a team of 13 partners will cover the years 2021-2024.

The goal is to develop an innovative technology to recover more than 98% of the raw materials, a percentage not reached by any current process, without losing valuable components. The second part of the project deals with the circular closure of the production chain by testing the creation of new panels produced with the just recovered raw materials.

What are the steps?

First comes the disassembly unit to separate the frame from the cables.

Second, an innovative delamination technology aims for the complete separation of the layers by avoiding the cross-contamination of the materials, in order to provide the maximum possible added value for the secondary raw materials. To deal with the various construction techniques of panels, several "cold" processes (not including high heating) are tested: mechanical delamination by diamond wire cutting, fluid delamination by applying CO2 in a specific state, and optical delamination by using a flashlight.

Third, it's the turn of the extraction of most valuable metals (such as silver, silicon, and gallium) through innovative processes of Ionic Liquid extraction and electrowinning. These are technologies that exploit the reactivity of liquid molten salts and electrochemical processes, in order to chemically degrade the delaminated layers, isolating pure metal crystals.

Fourth and last, to reach the full circularity new design techniques and process engineering will be experimented with in order to transform the just recovered waste into new components for panels.

The time to install a photovoltaic panel is now. At the end of its use, in about 30 years, a new effective disassembling industry will already be born, realizing new value from this new massive waste.

By becoming a premium supporter, you help in the creation and sharing of fact-based optimistic news all over the world.